TK Elevator Test Tower

The TK Elevator Test Tower (TKT) in Southern Germany was built to test new types of highspeed elevator. It boasts not only a magnificent view from the top, but also various technical features such as a textile façade and an active pendulum.

Located at Rottweil in south-west Germany, the 246 m high TK Elevator Test Tower is one of the tallest structures in Germany. Its purpose is the testing and certification of high-speed elevators such as the MULTI system in which elevator cars travel not only vertically, but also horizontally. However, the tower is more than just a functional structure for researching and developing modern elevator technologies.

There is a platform open to the public at a height of 232 m. From here, the highest such platform in Germany, visitors can enjoy breathtaking panoramic views of the surrounding landscape. Further, the tower is also the world’s tallest textile-clad structure. Inside the tower there is room for 10 elevator shafts, a firefighting lift and a glazed panoramic elevator

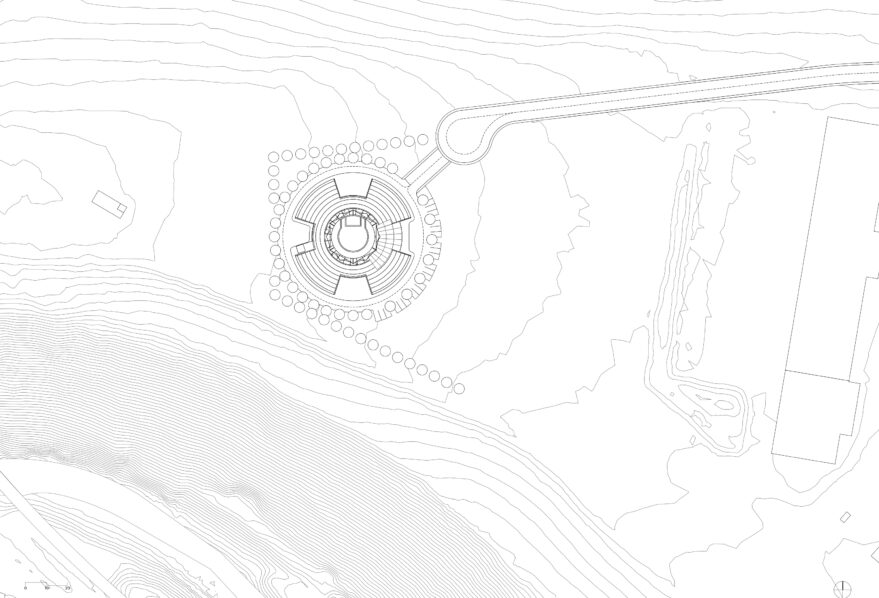

The 20.80 meter diameter reinforced concrete tube structure is designed as a vertical cantilever fixed in the ground (Fig. 3). The subsoil here consists of a Lower Keuper formation and a bearing stratum of shelly limestone. A 48 meter diameter building surrounding the base of the tower provides further horizontal restraint.

The inside of the TKT consists mainly of the walls for the elevator shafts, with floor slabs over part of the interior providing access to the shafts. Up to a height of 110 meter the external wall is 40 centimeter thick, above that 25 centimeter. To comply with the requirements of slipforming, the maximum concrete grade was limited to C50 / 60

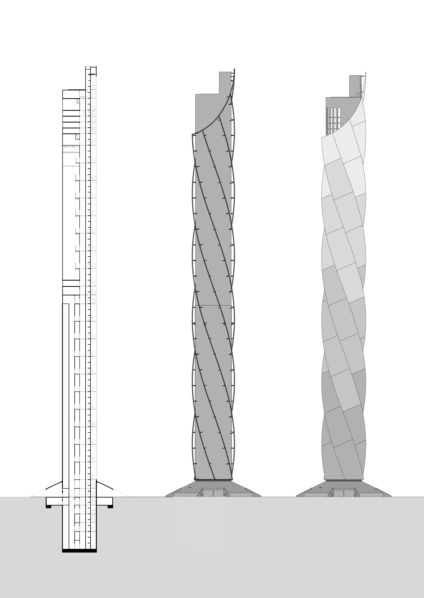

The design of the textile facade was very demanding. It was necessary to consider not only erection and wind loads, but also maintenance and weather resistance. Many agreements with manufacturers, material appraisals, trials and mock-ups were needed because a textile facade on this scale had never been built before.

The tower’s textile facade is made from a PTFE-coated glass-fibre fabric, with the density of the weave decreasing over the height. The textile facade is attached to six steel circular hollow sections that wind their way up the outside of the tower at a distance of 1.80 meter from the concrete core.

Apart from its architectural function, the textile cladding has technical advantages, too. The steel support structure is in the form of helical strakes, which influence the vortex shedding and reduce wind loads by about 40 %. The cladding also shades the concrete structure and thus reduces the thermal stresses due to solar gains.

Wind tunnel tests revealed that the wind-induced transverse oscillations could not be fully eliminated by the textile cladding. Therefore, a system of dampers has to counteract the oscillations. The pendulum is suspended from a height of 200 meter on long ropes. The weights are concrete slabs that were raised into position on hydraulic jacks.

The pendulum responds passively to windinduced oscillations, but can also be used actively to set the tower in motion and thus allow the development engineers to simulate wind loads on the elevators. It can generate horizontal deflections of up to 200 millimeter at the top of the tower.

The TK Elevator Test Tower is the only high-rise structure in the world that can actively induce vibrations.

The viewing platform is located just below the top of the tower at a height of 232 meter. It comprises the socalled penthouse in the middle – a lightweight steel structure with a roof of trapezoidal profile sheeting – surrounded by an open terrace behind a 4 meter high glass screen. The panes of glass are fixed to tapered steel sections.

Such a transparent structure permits stunning views, with even the Alps visible in good weather. In terms of engineering and architecture, the TK Elevator Test Tower was an extremely challenging structure that called for close cooperation between design team, contractor and client.